When Process Scale Takes a Leap, You Need a More Powerful Separation Engine

In advanced bioprocesses such as monoclonal antibody production, cell therapy, and viral vector purification, 5L-scale material handling is becoming the new standard. Faced with the high acquisition and maintenance costs of international brand equipment and lengthy supply chain cycles, cost control and efficiency optimization in scaled production encounter severe challenges.

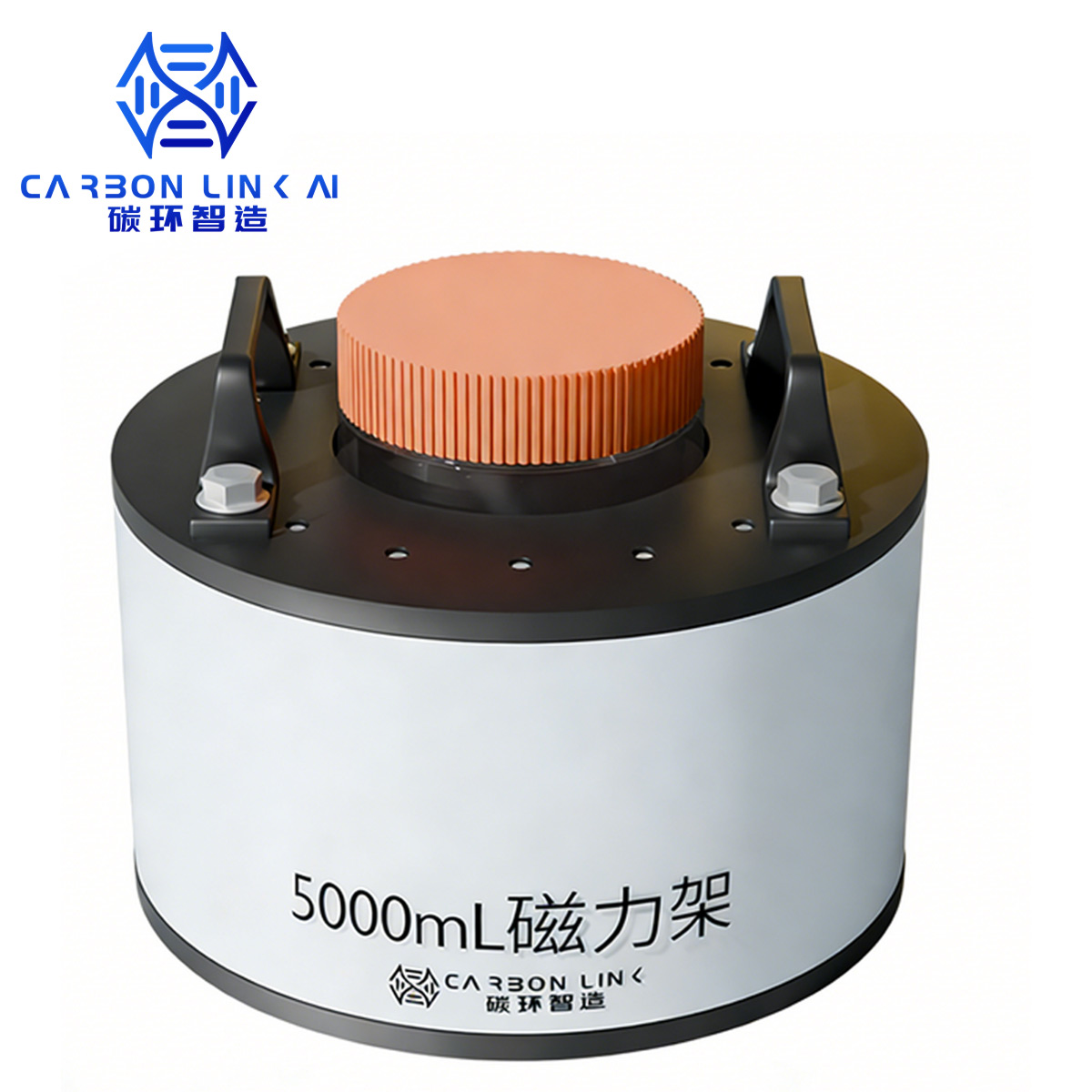

Carbonlinkai, as an expert deeply focused on OEM and high-end customization of magnetic separation technology, meticulously analyzes the technological core and industrial requirements of top brands like SEPMAG. We introduce the 5L Industrial-Grade Magnetic Bead Separator System. We not only provide an excellent top-tier internationally-caliber “alternative” with performance directly benchmarked against top-tier internationallys but also, with our deep collaborative R&D and flexible smart manufacturing capabilities, become your reliable core equipment partner in the process chain.

Core Value: Why Are We an Exceptional Alternative to SEPMAG?

1. Performance Strength: Benchmarking Top-Tier, Defining a New Separation Standard

Globally Uniform, High-Strength Magnetic Field Engine: Employs a “Multi-Ring Focused Magnetic Circuit System” paired with N52 and higher-grade neodymium (NdFeB) magnetic materials. This constructs a magnetic field environment within the full 5L working space that is high-strength (surface field strength >0.6T) and highly uniform (deviation <±10%). Ensures rapid, synchronous, and complete adsorption of micron-sized magnetic beads, with separation time and yield data comparable to original top-tier internationallyed equipment.

Forged for Continuous Production: The main body utilizes a heavy-duty stainless steel integrated frame and an engineered anti-tip base. Having undergone rigorous dynamic load testing, it ensures absolute stability and zero-fault operation under conditions of continuous batch production, full 5-liter liquid load, and frequent movement.

Intelligent Upgrade Interface (Modular Option): Natively supports the integration of electric lift, multi-dimensional oscillation, in-process optical monitoring, and PLC communication interfaces. It can seamlessly connect to automated production lines, enabling a smooth upgrade from “manual operation” to an “intelligent separation unit.”

2. Deep Customization Capability: Your Process, Co-“Coded” by Us

Co-Creation Model from Requirement to Delivery: We act as your extended R&D team. Based on your specific cell type, magnetic bead characteristics, buffer system, container configuration, and upstream/downstream interfaces, we conduct magnetic circuit simulation, structural design, and prototype validation to ensure the perfect fit between the equipment and your process.

Full-Dimensional Customization, Mastering Every Detail:

Magnetic Performance Customization: Standard uniform field for efficient capture; customizable radial/axial gradient fields to handle complex impurity backgrounds or fine-gradient elution.

Material & Compliance Customization: Provides 316L VIM-grade stainless steel, PEEK, or special coatings to meet requirements for biocompatibility, corrosion resistance, high-temperature sterilization, and cGMP/GLP environments.

Function Integration Customization: Can embed functions such as temperature control modules (-20°C to 80°C), online turbidity/pH sensors, and RFID material tracking.

Branding & Aesthetics Customization: Offers a complete branding solution, from industrial design and corporate color finishing to exclusive markings.

3. Disruptive Cost Advantage: Redefining Return on Investment

Performance Benchmarking, Cost Restructuring: Achieves direct performance benchmarking against products like SEPMAG in core separation efficacy (adsorption rate, recovery rate, batch-to-batch consistency). Through a vertically integrated supply chain and lean production, we offer “top-tier internationally-grade performance at a domestic advantage price,” potentially reducing total cost of ownership by 40%-60%.

Source Smart Manufacturing, Agile Response: As a source expert integrating R&D, production, and service, we provide full-process companion support from proof-of-concept, pilot scale, to scaled-up production. Our response speed far exceeds the traditional agency model, helping you accelerate process development and time-to-market.

Application Scenarios: Empowering Key Biomanufacturing Stages

Large-Scale Biopharmaceuticals: Scaled downstream capture and purification of monoclonal antibodies, ADC drugs, viral vectors (AAV/LV), handling large-scale cell culture supernatants or lysates.

Advanced Therapy Medicinal Products (ATMPs): Key steps in the production of products like CAR-T and stem cell therapies, such as immunomagnetic bead cell sorting and magnetic bead-based nucleic acid removal.

Vaccine Production: Industrial-scale purification of recombinant protein vaccines and virus-like particles (VLPs).

IVD Core Raw Material Preparation: Batch production and quality control of ultra-large quantities of nucleic acid extraction magnetic beads and chemiluminescence magnetic beads.

Cooperation Models: Initiating Flexible, Win-Win Partnerships

OEM/ODM Manufacturing: Strictly adheres to your technical specifications, quality systems, and branding requirements for confidential production and delivery.

Joint Development (JDM): For your disruptive new process, we jointly initiate projects and develop customized systems from the ground up.

Standard Product Quick Purchase: Choose from our mature platform products to enjoy fast supply and high cost-effectiveness.

Carbonlinkai — More Than an Alternative, Committed to Surpassing. Making High-End Magnetic Separation Technology Accessible to Every Innovative Enterprise.

Main Technical Parameters for the Global magnetic rack OEM expert carbonlinkai 5L Large Volume Magnetic Bead Separators (SEPMAG Alternative):

Optimal Working Volume: 200mL – 5000mL

Recommended Container: Compatible with Shuniu 5000mL reagent glass bottles.

Operating Procedure for the Global magnetic rack OEM expert carbonlinkai 5L Large Volume Magnetic Bead Separators (SEPMAG Alternative):

1.Place the tube containing the mixed solution of magnetic beads bound to the target onto the magnetic bead separation system.

2.Allow it to stand for 1 minute, or until all magnetic beads are collected against the tube wall.

3.Carefully decant or aspirate the supernatant using a pipette.

4.Remove the container from the system and place it back on the bench. The magnetic separation is now complete.

Phone

Phone

Leave a comment