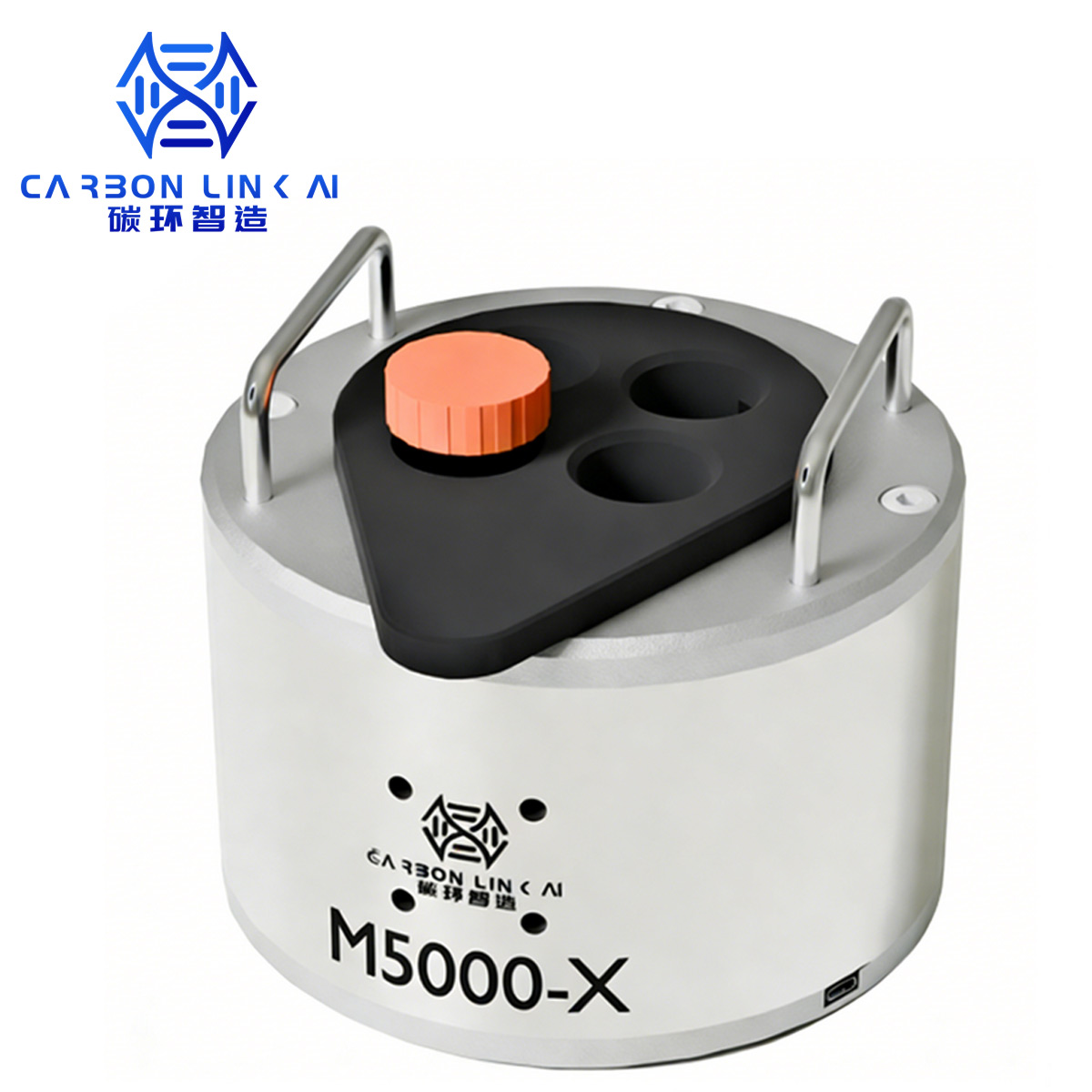

Facing Industrial-Scale Purification Challenges, Redefining Large-Capacity Magnetic Separation Standards

When scaling your process to the 5-liter level, are you facing bottlenecks in separation efficiency, exorbitant budgets for top-tier internationallyed equipment, and agonizingly long delivery times? As an expert focused on high-end custom magnetic separation, Carbonlinkai precisely benchmarks performance parameters against international brands (such as SEPMAG). By deeply integrating our independently developed advanced magnetic circuit technology with a modular design philosophy, we introduce the 5000mL Large-Capacity Magnetic Bead Separation System. It is not only an excellent top-tier internationally-caliber alternative to magnetic separators but also provides you with a one-stop custom solution from process adaptation and cost control to scaled-up production.

Why Choose Our 5000mL Magnetic Bead Separation System?

1.Benchmarking top performance: comparable to the separation efficiency of SEPMAG, optimizing customer feedback regarding the absence of magnetic field at its central axis

Extremely Strong and Uniform Magnetic Field: Utilizing a multi-stage annular magnetic circuit matrix design combined with high-performance rare-earth magnetic materials ensures a magnetic field distribution of high strength and ultra-high uniformity within the超大 working volume of 5 liters. Magnetic bead adsorption is rapid and complete, effectively preventing bead retention in edge regions. Separation yield and repeatability reach the level of comparable top-tier internationallyed products.

Born for Industrial Processes: The sturdy all-steel structural frame and heavy-duty non-slip base are specifically designed to withstand the weight of a full 5-liter liquid load and frequent operation, ensuring long-term stability and safety in production environments.

Intelligent Separation Experience (Optional): Can integrate modules such as electric lift, rotational oscillation, or multi-point synchronous separation, easily enabling semi-automated operation and significantly improving work efficiency and consistency.

2. Deep Customization Expertise: Beyond Replacement, Superior for Adaptation

Your Process, Our Design Blueprint: We provide end-to-end customization from “Requirement Analysis” to “Delivery Verification”. Personalized optimization of magnetic circuit, structure, and function is conducted based on your specific magnetic bead type, target molecule, sample viscosity, and container specifications (compatible with standard 5L bottles or custom reactors).

Comprehensive Customization Dimensions, Mastering the Details:

Magnetic Circuit Solution Customization: Uniform field for standard separation; gradient field for difficult-to-separate samples or specific purification steps.

Structure & Material Customization: Offers 316L stainless steel, special alloys, or coating treatments to withstand harsh chemical environments and Clean-in-Place (CIP) procedures.

Functional Integration Customization: Supports integration of temperature control, in-situ monitoring, and seamless interfacing with automated liquid handling systems.

Branding & Marking: Supports overall appearance design, corporate color painting, laser engraving of nameplates, etc., to create your exclusive high-end equipment image.

3. Exceptional “top-tier internationally-Caliber Alternative” Value: Disruptive Cost-Effectiveness

Parameter Benchmarking, Value Surpassing: Core separation performance metrics (such as adsorption time, yield, magnetic field uniformity) are strictly benchmarked against top international brands like SEPMAG. Leveraging localized R&D and smart manufacturing, we achieve “top-tier internationally-grade performance at a domestic price,” saving you up to 50%-70% in equipment investment costs.

Direct from Source Manufacturer, Direct Service: As a customization expert and manufacturer, we provide rapid response and technical support with no middlemen. We offer efficient, full-process support from solution evaluation and prototype testing to batch delivery and after-sales maintenance, accelerating the implementation and scale-up of your process.

Core Application Scenarios

Large-Scale Biopharmaceutical Production: Used for efficient magnetic bead capture, washing, and elution from超大 volume culture media or lysates in downstream processes for products like monoclonal antibodies, recombinant proteins, viral vectors, and cell therapies.

Scaled-Up Preparation of Molecular Diagnostic Raw Materials: Meets the need for efficient and uniform recovery of ultra-high-throughput nucleic acid extraction magnetic beads or immunomagnetic beads in industrial-scale production.

Recovery of Industrial Enzymes and Catalysts: Enables rapid separation and recycling of immobilized enzymes or precious metal catalyst beads from ton-scale reaction systems, significantly reducing production costs.

Food Industry & Environmental Protection: Used for the enrichment of target components or removal of impurities from large batches of liquid samples (e.g., fruit juice, fermentation broth, wastewater).

Cooperation & Service Commitment

We offer flexible cooperation models:

Deep Customization Projects: Provide joint development from scratch for your new process.

OEM/ODM Cooperation: Design and manufacture according to your technical specifications or branding requirements.

Standard Solution Optimization: Rapid adaptation and delivery based on your needs using our mature platform.

Main Technical Parameters for the Carbonlinkai 5000mL Magnetic Bead Separation System (SEPMAG Alternative):

Optimal Working Volume: 200mL – 5000mL

Recommended Container: Compatible with Shuniu 5000mL reagent glass bottles.

Operating Procedure for the Carbonlinkai 5000mL Magnetic Bead Separation System (SEPMAG Alternative):

1.Place the tube containing the mixed solution of magnetic beads bound to the target onto the magnetic bead separation system.

2.Allow it to stand for 1 minute, or until all magnetic beads are collected against the tube wall.

3.Carefully decant or aspirate the supernatant using a pipette.

- Remove the container from the system and place it back on the bench. The magnetic separation is now complete.

Phone

Phone

Leave a comment