When shopping for a vacuum centrifugal concentrator, do you have a lot of doubts in the face of different brands, models and parameters? In 5 simple steps, CarbonFiber teaches you how to choose the right vacuum centrifugal concentrator for your application with a low budget:

1 :Look at the solute type

Solutes are mainly divided into two categories: biological (DNA, RNA, enzymes, proteins, vaccines, etc.) and non-biological (organic synthesis products, drug metabolites, pesticides, etc.).

Non-biological products

The technique used to concentrate and dry samples of non-biological products is vacuum evaporation. These samples usually contain high concentrations of organic solvents and/or strong acids and bases. Vacuum concentration allows for rapid concentration of non-biological materials.

Biological preparation

There are two ways of concentrating biologics: freeze-drying (lyophilization) and vacuum concentration.

Freeze-drying: Freeze-drying is often recommended when the material is to be stored for a long period of time, must be easily and quickly recovered, and needs to remain biologically active (i.e., proteins/enzymes); freeze-drying can be efficiently performed in a vacuum centrifugal concentrator. Freeze drying in some cases requires deep vacuum (i.e., rotary vane oil pumps) to keep the sample frozen during sublimation.

Vacuum Concentration: Most molecular biology applications involving DNA/RNA in aqueous or aqueous + low organic concentrations do not require the added cost of a cold trap. Non-corrosive solvent solvents (ethanol, methanol, acetonitrile), there is also no need to choose a vacuum centrifugal concentrator with a cold trap; these 2 types of configurations can be selected by referring to the CarbonFiber CV100-TH parameters for vacuum concentration of prepared samples.

2: Look at the solvent type

Depends on the nature of the solvent used for the sample: corrosive solvents (dichloromethane, toluene); high-boiling solvents (DMSO, DMF); the configuration can be referred to the parameters of the CarbonFocus TH-200, which can be customized according to the solutes and solvents to program the vacuum and temperature. Cold trap, PTFE coated centrifugal chamber and corrosion-resistant diaphragm vacuum pump are equipped as standard for high corrosion resistance.

3:Look at the vessel specifications

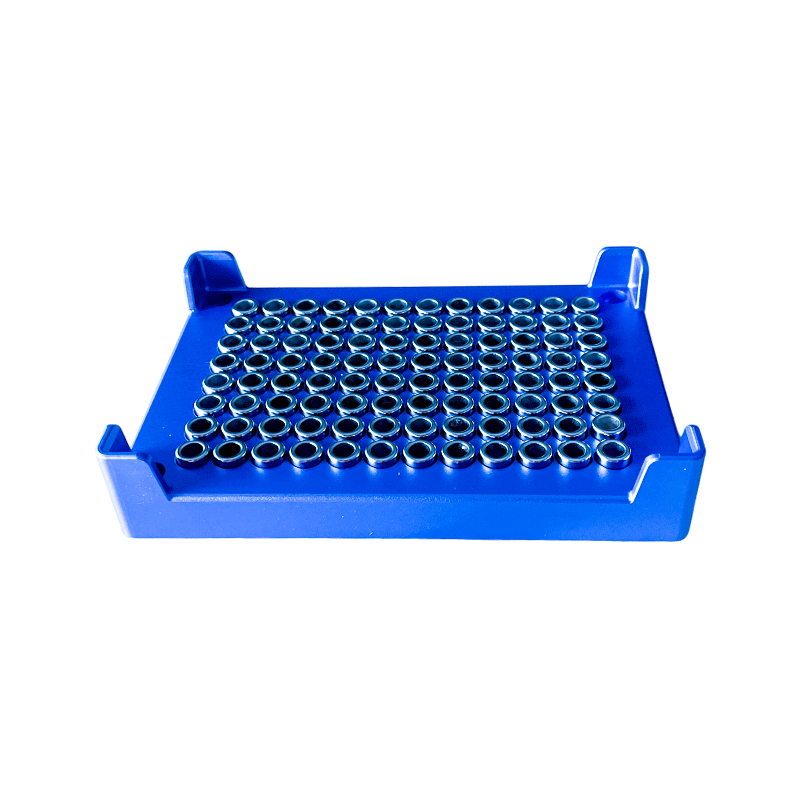

Rotor selection is based on the working volume of the sample and the number of tubes/plates or containers.

4:Easy to assemble

In general, it is recommended to choose the all-in-one intelligent vacuum centrifuge concentrator, which is easy to program according to the experimental scenarios, meets a variety of uses, and can be used directly out of the box without assembly;.

5:Basic configuration is good enough

No need to pursue big and complete, the basic configuration is good enough, for example, you only use aqueous solvents, choose enough configuration can be, no need to kill the chicken with a cattle knife, buy vacuum centrifugal concentrator to meet the water and corrosive two solvents at the same time. Do not have to usually do not need the function, spend more tens of thousands of tens of thousands of budget, after all, the use of good low-cost this killer application, can build friends do not have a competitive advantage. Special scenarios need to go to the rental platform for short-term rental, more cost-effective than buying.

Leave a comment